Best Woodworking Tools Manufacturer

In today’s competitive manufacturing and furniture industry, woodworking tools play a crucial role in shaping quality, speed, and precision. Whether a small workshop crafts custom cabinets or a large factory produces modular furniture, the right tools directly influence productivity and customer satisfaction. Therefore, businesses that invest in advanced equipment often experience faster output, better finishing, and stronger brand trust.

Moreover, customers now research deeply before purchasing any machinery. They compare durability, safety, automation features, and after-sales service. As a result, companies that provide reliable solutions and informative guidance gain higher visibility on search engines and stronger engagement from potential buyers. Consequently, a well-equipped workshop not only produces furniture; it also builds reputation and long-term profitability.

Why Quality Woodworking Tools Matter for Every Business

Quality woodworking tools are not just machines; they are the backbone of any successful workshop. The right equipment improves workflow, maintains product quality, and supports long-term business growth. When businesses invest in reliable tools, they create a strong foundation for efficiency and customer satisfaction.

01. Smooth Operations & Consistent Results

High-quality cutters, planers, and saws reduce material waste and save production time. Accurate machines help craftsmen produce uniform designs that match modern standards, which builds customer trust.

02. Better Safety & Reduced Worker Fatigue

Advanced safety guards, dust extraction systems, and ergonomic handles minimize workplace risks. As a result, employees work more comfortably, and accidents decrease, leading to uninterrupted operations.

03. Higher Productivity & Profit Growth

When tools perform efficiently, downtime reduces and output increases. Faster production with fewer errors directly improves profitability and overall business performance.

04. Easy Scalability for Future Demand

Efficient woodworking machines allow workshops to increase production without compromising quality. Therefore, smart investment today prepares the business to handle larger orders and future opportunities confidently.

Essential Woodworking Tools Every Workshop Should Own

A professional setup usually includes multiple categories of machinery and hand tools. However, the most impactful ones form the backbone of any workshop. These tools deliver versatility, efficiency, and consistent finishing.

01. Cutting and Shaping Tools That Ensure Precision

Circular saws, band saws, and jigsaws provide clean and accurate cuts. Routers and chisels shape edges and decorative profiles. Because these tools define the structure of every product, accuracy becomes non-negotiable. Skilled craftsmen often rely on adjustable speed controls and sharp blades to maintain detail and symmetry.

02. Measuring and Marking Tools for Perfect Alignment

Tape measures, digital calipers, try squares, and marking gauges guarantee dimensional accuracy. Although these tools may seem basic, they prevent costly errors. When measurements stay consistent, assembly becomes seamless, and finishing looks professional.

03. Finishing Tools That Elevate Final Appearance

Sanders, polishers, and spray systems refine the surface and enhance durability. Smooth finishes attract customers immediately, while protective coatings increase product lifespan. Therefore, finishing tools often decide whether a product looks average or premium.

How Advanced Woodworking Tools Increase Productivity

Modern technology has revolutionized workshop efficiency. Computer-assisted cutting, automated feeding systems, and laser alignment drastically reduce manual effort. As a result, craftsmen focus more on creativity and less on repetitive tasks.

01. Automation and Smart Features

Smart sensors, programmable controls, and digital displays allow operators to achieve precision quickly. Machines adjust settings automatically, which reduces errors. Consequently, production speed increases while waste decreases.

02. Energy Efficiency and Cost Savings

New-generation equipment consumes less electricity and operates quietly. Although the initial investment might appear high, long-term savings justify the decision. Workshops notice reduced utility bills and longer machine lifespans, which ultimately improve return on investment.

Choosing the Right Woodworking Tools for Your Needs

Every workshop differs in scale and specialization. Therefore, selecting equipment requires careful analysis rather than impulse buying. Buyers should evaluate production goals, available space, and technical support before finalizing purchases.

01. Understanding Material Compatibility

Different woods demand different cutting speeds and blade strengths. Hardwood tools must withstand resistance, whereas softwood machines emphasize speed. Consequently, compatibility ensures longevity and performance stability.

02. Evaluating After-Sales Service and Support

Reliable suppliers provide installation guidance, training sessions, and spare parts availability. Continuous support prevents unexpected downtime. Because maintenance becomes easier, workshops operate smoothly even during peak demand.

H4: Benefits of Investing in Professional Woodworking Tools

Investing in professional woodworking tools gives workshops long-term advantages in quality, productivity, and brand value. Advanced equipment not only improves daily operations but also strengthens market reputation and customer relationships.

I. Improved Output Quality

Professional machines deliver precise cuts and smooth finishing, which results in high-quality and uniform products every time.

II. Faster Production Timelines

Advanced tools reduce manual effort and speed up processes, allowing workshops to complete orders quickly and handle more projects efficiently.

III. Increased Customer Trust

Consistent finishing and reliable delivery build confidence among customers, which encourages repeat business and long-term loyalty.

IV. Enhanced Brand Reputation

Durable and visually appealing products create a strong brand image. Positive word-of-mouth spreads faster and attracts new customers.

V. Long-Term Business Growth & Marketing Value

Better reviews and online visibility improve search presence. Therefore, investing in professional tools becomes a strategic growth decision, not just an operational upgrade.

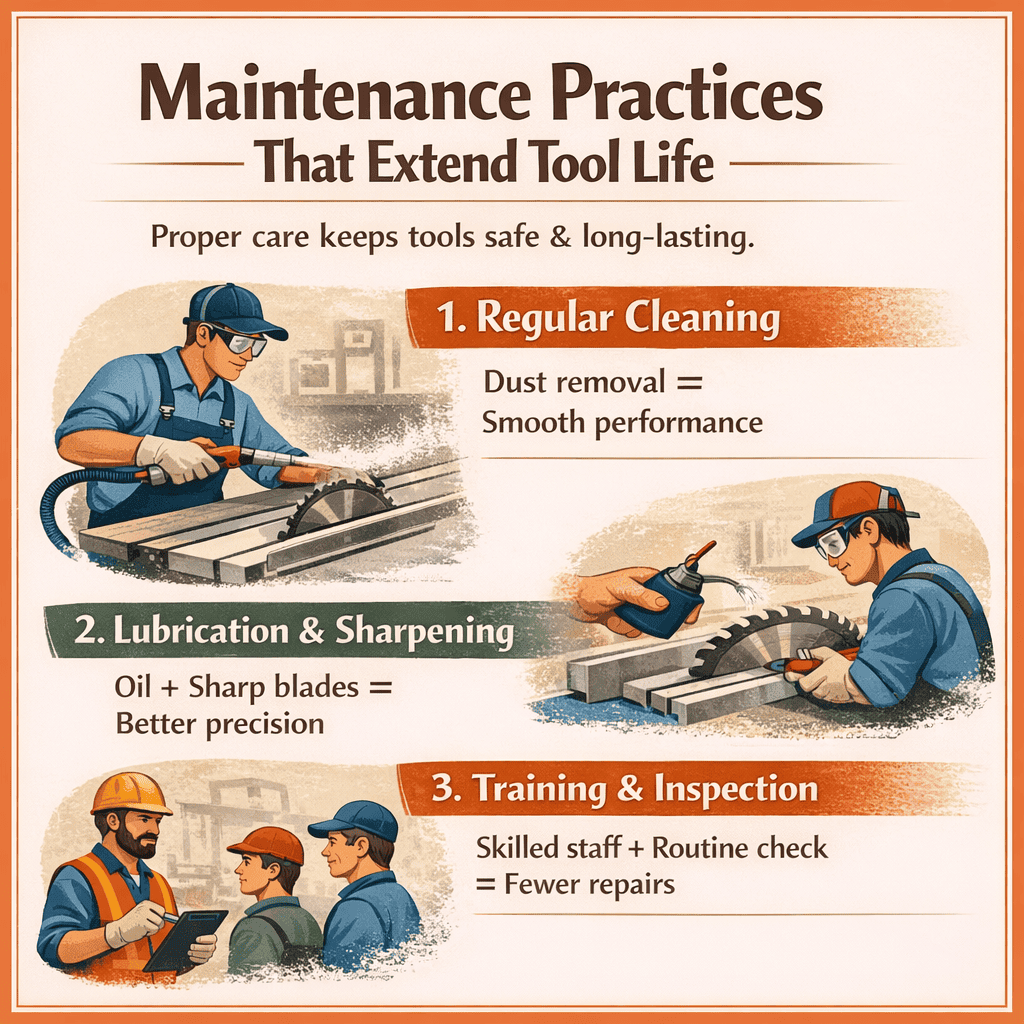

Maintenance Practices That Extend Tool Life

Proper maintenance keeps woodworking tools efficient, safe, and long-lasting. When workshops follow regular care routines, they reduce breakdowns, maintain precision, and save long-term costs.

I. Regular Cleaning & Dust Removal

Removing dust and debris prevents overheating and mechanical wear. Clean machines run smoother and maintain consistent performance.

II. Lubrication, Calibration & Blade Sharpening

Lubricating moving parts and calibrating settings ensure accuracy. Sharp blades and aligned components improve cutting precision and reduce strain on the machine.

III. Staff Training & Periodic Inspection

Trained operators follow safety protocols and understand machine limits. Routine inspections identify minor issues early, which prevents major repairs and protects both tools and the workforce.

Future Trends in Woodworking Tools and Technology

The woodworking industry is continuously evolving with innovation and digital integration. New technologies and eco-friendly approaches are helping businesses become stronger in the future and stand out in the competitive market.

1. Digital Innovation & Automation

Artificial intelligence, automated design software, and robotics are making production lines faster and more accurate. Workshops that adopt these technologies early gain higher efficiency, better output, and a strong competitive advantage.

2. Sustainability & Eco-Friendly Solutions

Eco-friendly coatings, low-energy motors, and recyclable materials attract environmentally conscious buyers. When businesses combine technology with sustainability, they build long-term growth and a stronger position in the global market.

Final Thoughts on Choosing the Right Woodworking Tools

Woodworking success depends on more than craftsmanship alone. The right selection of woodworking tools, consistent maintenance, and smart upgrades collectively define productivity and profitability. When workshops invest strategically, they achieve superior quality, safer environments, and faster delivery timelines.

Moreover, customers recognize professionalism through precision and attention to detail. Consequently, well-equipped businesses gain stronger online visibility, improved customer loyalty, and sustainable growth. By continuously upgrading knowledge and technology, any workshop can transform into a modern, efficient, and highly respected production space.